Special Price for Black Silicon Carbide F16 - Silicon Carbide Cantilevers Paddle – Anteli

Special Price for Black Silicon Carbide F16 - Silicon Carbide Cantilevers Paddle – Anteli Detail:

Product detailed and application

Large wafer loading force silicon carbide SiSiC / SiC cantilever paddle / beam is suitable for a robot automatic loading and handling system because it has stable performance, non-deformation in high temperature and large wafer loading force. Since the section of the cantilever paddle is stable with no deformation, it is possible to make larger size wafer using existing furnace tubes. Large wafer loading force silicon carbide SiSiC / SiC cantilever paddle / beam can be applied to LPVCD on basis of its similar thermal expansion coefficient with LPVCD coating, which greatly prolongs the maintenance and cleaning cycle,and significantly reduce pollutants.

Technical parameters of reaction bonded silicon carbide RBSIC :

| item | unit | data |

| Temperature of application | ℃ | 1380 |

| density | G/cm3 | >=3.02 |

| Open porosity | % | <0.1 |

| Moh’s Scale of Hardness | 13 | |

| Bending strength | Mpa | 250(20℃) |

| Mpa | 280(1200℃) | |

| Modulus of elasticity | Gpa | 330(20℃) |

| Gpa | 300(1200℃) | |

| Thermal conductivity | W/m.k | 45(1200℃) |

| Coefficient of thermal expansion | K-1*10-6 | 4.5 |

| Acid-proof alkaline | Excellent |

Features:

a. It does not deform at high temperature and the wafer loading force is large;

b. Excellent thermal shock resistance and long service life;

c. The thermal expansion coefficient of the cantilever paddle is extremely small, which greatly prolongs the maintenance and cleaning cycle;

and drastically reduce pollutants

Other kiln furniture made by silicon carbide ceramic

Besides Reaction sintered silicon carbide SiSiC cantilever paddle for wafer loading, we also produce other kiln furniture including RBSIC/SISIC silicon carbide beams, nozzle tubes, spiral nozzle tube, swirl nozzle tube, oxide bonded SIC silicon carbide batts/setter plate and RBSIC cooling pipes.

Wear resistant RBSIC/SISIC silicon carbide products

Because our RBSIC/SISIC silicon carbide product have the advantages of excellent wear resistance, corrosion resistance and long service life, it can also be made into wear resistant linings which can be easily installed in processing pipes or cyclones.

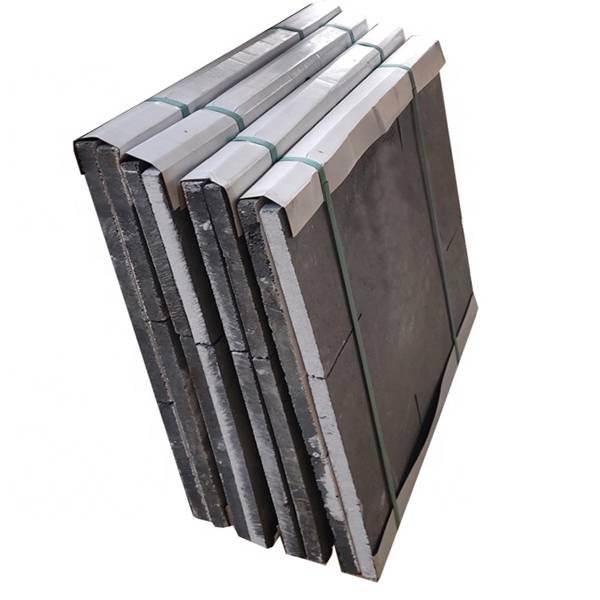

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for Special Price for Black Silicon Carbide F16 - Silicon Carbide Cantilevers Paddle – Anteli , The product will supply to all over the world, such as: Anguilla, Comoros, Estonia, Our products are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.