Special Design for Silicon Carbide Grinding Types Gc2000 - silicon carbide radiant tube and heat exahangers – Anteli

Special Design for Silicon Carbide Grinding Types Gc2000 - silicon carbide radiant tube and heat exahangers – Anteli Detail:

product detailed

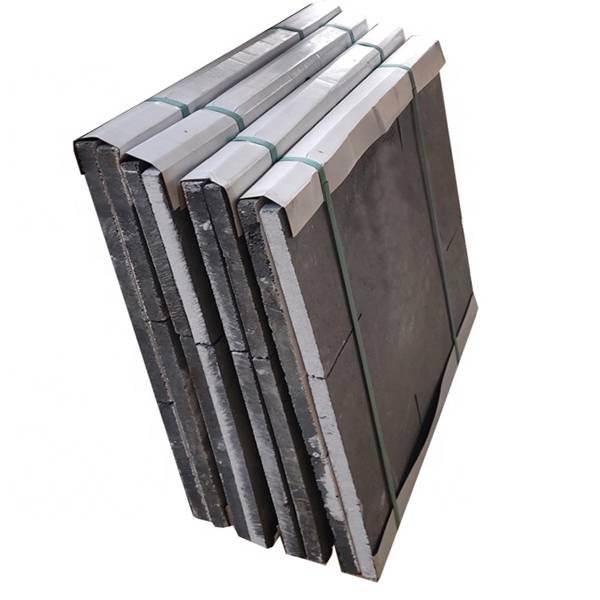

Rbsic (sisic) radiation tubes have superior characteristic such as corrosion resistance, high temperature tolerance, oxidation resistance, superior thermal conductivity, bending strength, long time service life, etc. They are also very efficient, energy-saving, enviromental protection in the field of industrial production.

Application

The series of radiation tubes are widely used in the annealing production lines for industries of steels and metallurgies. They are also used for heat conduction system and radiant system under the conditions of high temperature, high corrosion and high wear resistance.

Characteristics

a. High temperature tolerance

b. Superior corrosion resistance

c. Excellent abrasion resistance

d. Perfect Thermal conductivity.

Other RBSiC / SiSiC reaction bonded silicon carbide products:

RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardnesshas high hardness, high temperature, abrasion resistance, oxidation resistance, acide and alkali resistance characteristics,which is widely used for wear-resisting lining of hydraulic cyclones, flue gas desulphurization pipes and coal slurry conveyor pipelines.

Thickness available: 4mm – 25mm

Shape available: Tubes , Tee pipes, Elbows, Cones, Rings and so on.

The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, coling air pipe,burner nozzles,thermocouple protecting tubes,temperature measuring parts, radiant tubes, desulfurization nozzles, crucible,batts, wear resistant lining materials,plates, seals, rings and special shaped structural parts.

FAQ

1.Can you supply sample?

Yes.We try our best to give you the free samples.

2.How about your After-sales service?

We promise that we can change products or refund if they have any quality problem.

3.When we can contact you?

You can contact us 24 hours every day.We are pleasure to service you at any time.

4.Can you give me a discount?

Yes,we can,If you have any inquiry,please contact us via email or other contact way. 5.What about your MOQ?

1piece

6.Are you trading company or manufacturer ?

We are factory and manufacturer

7. How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

8.Do you provide samples ? is it free or extra ?

Yes, we could offer the sample for free charge.

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

Our products are greatly recognized and trustworthy by users and will fulfill continually shifting economic and social requires for Special Design for Silicon Carbide Grinding Types Gc2000 - silicon carbide radiant tube and heat exahangers – Anteli , The product will supply to all over the world, such as: Holland, Hungary, Netherlands, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.