Manufacturing Companies for Sintered Silicon Carbide Micropowder - Wear Sleeves Tube – Anteli

Manufacturing Companies for Sintered Silicon Carbide Micropowder - Wear Sleeves Tube – Anteli Detail:

Product Detaill:

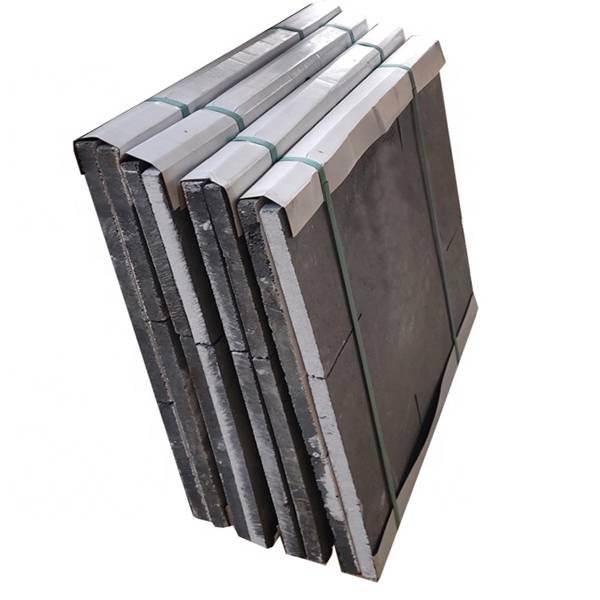

Refractory silicon carbide liner bushing sic sleeve for chemical pump Silicon carbide (SiC) is a lightweight ceramic material with high strength properties, excellent thermal conductivity, low thermal expansion, and is resistant to corrosion from acids. Because of its excellent properties, silicon carbide products are more and more widely applied in various fields nowadays.

We have professional advanced production line and inspeciton equipments to ensure high quality products. .Precision Ground and high polishing process. Advanced technology , precise grinding.

Characteristics

(1) high hardness, wear resistance and impact resistance.

(2) good corrosion resistance

(3) excellent mechanical strength

(4) good anti-oxidation

(5) good thermal shock resistance

(6) Low thermal expansion coefficient

(7) High thermal conductivity

(8) Excellent flatness and temperature resistance up to 1380℃)

(9) Good dimensional control of complex shapes.

(10) Easy installation.

(11) Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

(12)Various kinds of grades are availalbe based on customer’s application.

Application

Typical application of silicon carbide liner bushing

1.Mechanical Seal

2. Heat Exchanger

3. Armor Plate

4. Ball Valve Parts

5. Pump Components

6. Metallurgical Engineering

7. Water pump seals

Other RBSiC / SiSiC reaction bonded silicon carbide products:

RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardnesshas high hardness, high temperature, abrasion resistance, oxidation resistance, acide and alkali resistance characteristics,which is widely used for wear-resisting lining of hydraulic cyclones, flue gas desulphurization pipes and coal slurry conveyor pipelines.

Thickness available: 4mm – 25mm

Shape available: Tubes , Tee pipes, Elbows, Cones, Rings and so on.

The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, coling air pipe,burner nozzles,thermocouple protecting tubes,temperature measuring parts, radiant tubes, desulfurization nozzles, crucible,batts, wear resistant lining materials,plates, seals, rings and special shaped structural parts.

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for Manufacturing Companies for Sintered Silicon Carbide Micropowder - Wear Sleeves Tube – Anteli , The product will supply to all over the world, such as: Frankfurt, Korea, Chile, What is good price? We provide customers with factory price. In the premise of good quality, efficiency will have to be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products and solutions in time. Sincerely hope we could have long term business relationship.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!