Manufacturing Companies for Sintered Silicon Carbide Micropowder - Roller – Anteli

Manufacturing Companies for Sintered Silicon Carbide Micropowder - Roller – Anteli Detail:

Product Detail:

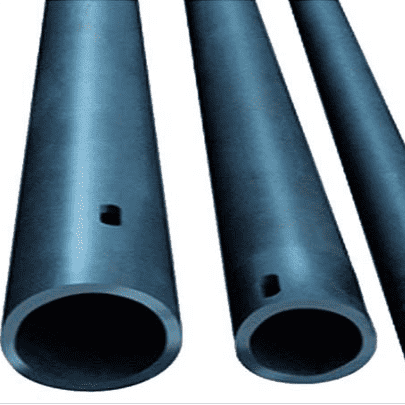

Reaction Sintered Silicon Carbide Rollers are characterized with excellent high-temperature bending strength, oxidation resistance, super wear resistance, free breaking in long-term use at a high temperature, free bending and deformation.

Application:

It can be applied to high-temperature firing zone of roller kilns for daily ceramics, sanitary porcelain, building porcelain, glass and magnetic materials. The service life is more than 10 times that of aluminum oxide ceramic rollers.

Major Technical Indicators of Reaction-sintered Silicon Carbide Products

|

Item |

Unit |

Data |

|

Operating Temperature |

℃ |

1380 |

|

Density |

g/cm³ |

≥3.02 |

|

Porosity |

% |

< 0.1 |

|

Bending Strength |

Mpa |

250(20℃) |

|

Mpa |

280 (1200℃) |

|

|

Elastic Modulus |

Gpa |

330(20℃) |

|

Gpa |

300 (1200℃) |

|

|

Thermal Conductivity |

W/m.k |

45 (1200℃) |

|

Thermal Expansion Coefficient |

K-1×10-6 |

4.5 |

|

Mohs Hardness |

13 |

|

|

Alkalinity and Acidity |

Excellent |

The Bending Strength of RBSiC (SiSiC) Roller is 250MP,safety coefficient is 5 times, and the length of bearing capacity of 1 meter. If the product length is L, the bearing capacity can be calculated with the following formula:

Concentrated Force = Surface Value 1/L, Resultant Force of Uniform Distribution Force = Surface Value *1/L. The adaptive temperature of the bearing capacity is 1380℃.

Roller Load-Bearing Capacity List

|

Length (m) |

Sectional Dimensions |

Concentrated Loading (kg) |

Uniformly Distributed Loading(kg) |

||

|

L |

D1 |

D2 |

δ |

||

|

1 |

35 |

23 |

6 |

70 |

140 |

|

1 |

40 |

28 |

6 |

97 |

194 |

|

1 |

45 |

33 |

6 |

130 |

260 |

|

1 |

50 |

38 |

6 |

167 |

334 |

|

1 |

55 |

44 |

7 |

261 |

522 |

|

1 |

60 |

46 |

7 |

283 |

566 |

|

1 |

80 |

46 |

8 |

604 |

1208 |

Packing:As requirements

Delivery time: 1*20GP container takes about 10-20days

MOQ: 5pieces

Samples: If Customer needed ,Free samples available and charge shipping

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Manufacturing Companies for Sintered Silicon Carbide Micropowder - Roller – Anteli , The product will supply to all over the world, such as: Grenada, Moscow, Barbados, Welcome to visit our company, factory and our showroom where displays various products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.