Manufacturing Companies for Flue Gas Desulfurization Spiral Jet Nozzle - Online Exporter China Sic Green Silicon Carbide Grain/Silicon Carbide Particle – Anteli

Manufacturing Companies for Flue Gas Desulfurization Spiral Jet Nozzle - Online Exporter China Sic Green Silicon Carbide Grain/Silicon Carbide Particle – Anteli Detail:

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we’re the lowest around for Online Exporter China Sic Green Silicon Carbide Grain/Silicon Carbide Particle, We sincerely hope to provide you and your company with a great start. If there is anything we will do to suit your needs, we shall be additional than pleased to do so. Welcome to our manufacturing facility for stop by.

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we’re the lowest around for China Abrasive Sand, Gc, More than 26 years, Skilled companies from all over the world take us as their long-term and stable partners. We are keeping durable business relationship with more than 200 wholesalers in Japan, Korea, USA, UK, Germany, Canada, France, Italian, Poland, South Africa, Ghana, Nigeria etc.

1.Product detailed

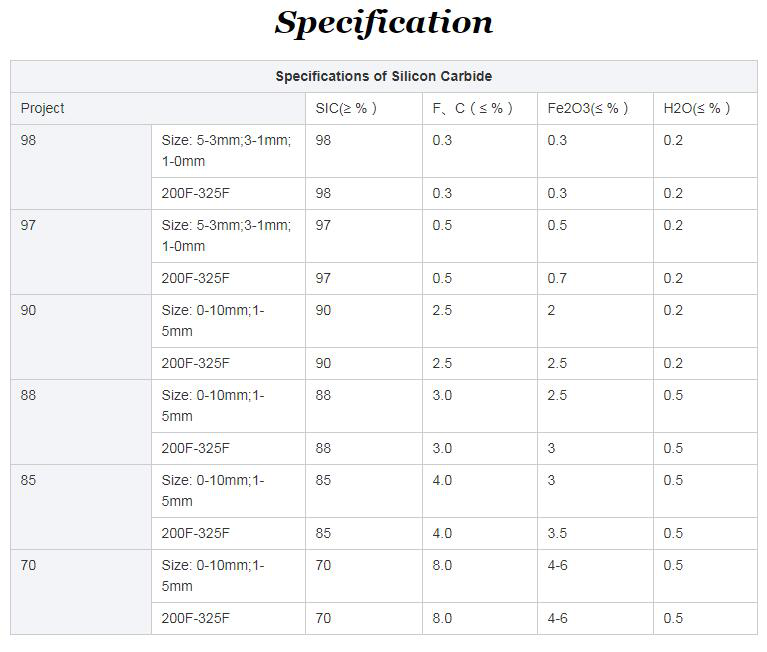

The black crystal silicon carbide with high density produced in our plant is made from high purity quartz sand and petroleum coke. The products are melted through high temperature up to 2500C in the electronic furnace. The products have high hardness good thermal endurance wear resistance, radiation resistance, thermal shock resistance, and good electrical and thermal conductivity,and are widely used in engineering ,chemistry ,electronic ,metallurgy and defense industries. Our company can produce different sizes of silicon carbide, according to the national and international standards GB,ISO,ANSI,FEPA,JIS, etc.

Silicon carbide (SiC), also known as carborundum, is a compound of silicon and carbon with chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Synthetic silicon carbide powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests. Electronic applications of silicon carbide such as light-emitting diodes (LEDs) and detectors in early radios were first demonstrated around 1907. SiC is used in semiconductor electronics devices that operate at high temperatures or high voltages, or both. Large single crystals of silicon carbide can be grown by the Lely method; they can be cut into gems known as synthetic moissanite. Silicon carbide with high surface area can be produced from SiO2 contained in plant material.

2.Characteristic

(1)Large melting furnace, longer melting time, lead to more crystallization, bigger crystals, higher purity and less impurities in producing Silicon carbide.

(2) Character of Silicon carbide: Good hardness, longer life.

(3) Chemical washed and water washed good cleanness.

(4) Special treated for Silicon carbide get higher purity, better toughness, and better grinding effect.

3.Application

Silicon carbide can be used as metallurgical deoxidizer and high temperature resistant materials in smelting.

Silicon carbide can also be used as abrasive materials,which can be used to make abrasive tools,such as grinding wheels, oilstones, grinding head and so on.

Silicon carbide is a new kind of reinforced steelmaking deoxidizing agent and ideal thermal insulating agent.it is used for deoxidizing. The usage dose is 14kg/t can make electricity consumption to reduce 15-20kw/h and time to reduce 15-20min per furnace to raise productivity rate to 8-10%.

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we’re the lowest around for Online Exporter China Sic Green Silicon Carbide Grain/Silicon Carbide Particle, We sincerely hope to provide you and your company with a great start. If there is anything we will do to suit your needs, we shall be additional than pleased to do so. Welcome to our manufacturing facility for stop by.

As for aggressive price ranges, we believe that you will be searching far and wide for anything that can beat us. We can easily state with absolute certainty that for such high-quality at such price ranges we’re the lowest around for Online Exporter China Sic Green Silicon Carbide Grain/Silicon Carbide Particle, We sincerely hope to provide you and your company with a great start. If there is anything we will do to suit your needs, we shall be additional than pleased to do so. Welcome to our manufacturing facility for stop by.

Online Exporter China Abrasive Sand, Gc, More than 26 years, Skilled companies from all over the world take us as their long-term and stable partners. We are keeping durable business relationship with more than 200 wholesalers in Japan, Korea, USA, UK, Germany, Canada, France, Italian, Poland, South Africa, Ghana, Nigeria etc.

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for Manufacturing Companies for Flue Gas Desulfurization Spiral Jet Nozzle - Online Exporter China Sic Green Silicon Carbide Grain/Silicon Carbide Particle – Anteli , The product will supply to all over the world, such as: United Kingdom, Swiss, Gambia, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.