Hot New Products Sintered Products With High Wear Resistance At Atmospheric Pressure - Silicon Carbide Beam – Anteli

Hot New Products Sintered Products With High Wear Resistance At Atmospheric Pressure - Silicon Carbide Beam – Anteli Detail:

Product detaill:

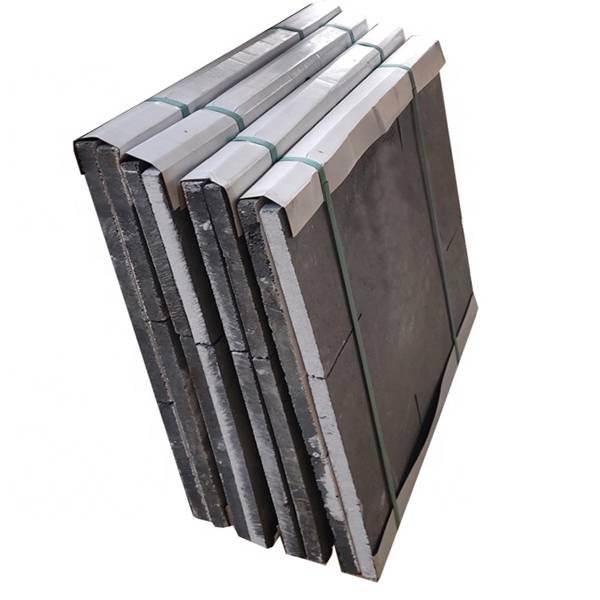

Reaction-sintered silicon carbide square beams are applicable for load-bearing structure frames of tunnel kilns, shuttle kilns, double-layer roller kilns and other industrial kilns. The product features in that the high-temperature bearing capacity is large, there is no bend or deformation in long-term use, and the service life is several times that of other materials, thus it is the ideal kiln furniture for sanitary porcelain and other electrical porcelain industries. The product is characterized with excellent high-temperature flexural strength, thermal shock resistance, oxidation resistance and free deformation in long-term use, thus can significantly reduce energy consumption without increasing the weight of the kiln car.

Major technical indicators of reaction-sintered silicon carbide products

Characteristic:

a.High temperature strength allows heavy loading weight

b.Excellent thermal shock resistance

c.High thermal conductivity

d.Excellent oxidation resistance translates to long life under high working temperature

Application

Silicon nitride and silicon carbide beams have excellent high-temperature flexural strength, creep resistance and oxidation resistance; mainly used in sanitary ceramics, high-voltage electrical porcelain, filters, quartz crucibles; shed plates and fish-shaped plates which are widely used in daily-use ceramic Industry; protection tube is used for temperature measurement in various industries; special-shaped products and burner sleeves are widely used in various kiln and mechanical engineering.

| Item | Data | Data |

| Operating Temperature | ℃ | 1380 |

| Density | g/cm³ | ≥3.02 |

| Porosity | % | < 0.1 |

| Bending Strength | Mpa | 250(20℃) |

| Mpa | 280 (1200℃) | |

| Elastic Modulus | Gpa | 330(20℃) |

| Gpa | 300 (1200℃) | |

| Thermal Conductivity | W/m.k | 45 (1200℃) |

| Thermal Expansion Coefficient | K-1×10-6 | 4.5 |

| Mohs Hardness | 13 | |

| Alkalinity and Acidity | Excellent |

| Length(m) | Sectional Dimensions | Concentrated Bearing Capacity(kg) | Resultant Force of Uniform Distribution Force(kg)

|

||

| L | B | H | δ | ||

| 1 | 30 | 40 | 6 | 130 | 260 |

| 1 | 40 | 40 | 6 | 165 | 330 |

| 1 | 40 | 50 | 6 | 235 | 470 |

| 1 | 50 | 70 | 7 | 526 | 1052 |

| 1 | 60 | 90 | 9 | 1059 | 2118 |

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

We are commitment to offer you the aggressive price tag ,exceptional products and solutions high-quality, as well as fast delivery for Hot New Products Sintered Products With High Wear Resistance At Atmospheric Pressure - Silicon Carbide Beam – Anteli , The product will supply to all over the world, such as: Johor, Argentina, Jordan, Establish long term and win-win business relationships with all our customers, share the success and enjoy the happiness of spreading our products to the world together. Trust us and you will gain more. Please feel free to contact us for more information, we assure you of our best attention at all times.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!