High Quality for Nsic - Wear Sleeves Tube – Anteli

High Quality for Nsic - Wear Sleeves Tube – Anteli Detail:

Product Detaill:

Refractory silicon carbide liner bushing sic sleeve for chemical pump Silicon carbide (SiC) is a lightweight ceramic material with high strength properties, excellent thermal conductivity, low thermal expansion, and is resistant to corrosion from acids. Because of its excellent properties, silicon carbide products are more and more widely applied in various fields nowadays.

We have professional advanced production line and inspeciton equipments to ensure high quality products. .Precision Ground and high polishing process. Advanced technology , precise grinding.

Characteristics

(1) high hardness, wear resistance and impact resistance.

(2) good corrosion resistance

(3) excellent mechanical strength

(4) good anti-oxidation

(5) good thermal shock resistance

(6) Low thermal expansion coefficient

(7) High thermal conductivity

(8) Excellent flatness and temperature resistance up to 1380℃)

(9) Good dimensional control of complex shapes.

(10) Easy installation.

(11) Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane)

(12)Various kinds of grades are availalbe based on customer’s application.

Application

Typical application of silicon carbide liner bushing

1.Mechanical Seal

2. Heat Exchanger

3. Armor Plate

4. Ball Valve Parts

5. Pump Components

6. Metallurgical Engineering

7. Water pump seals

Other RBSiC / SiSiC reaction bonded silicon carbide products:

RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardnesshas high hardness, high temperature, abrasion resistance, oxidation resistance, acide and alkali resistance characteristics,which is widely used for wear-resisting lining of hydraulic cyclones, flue gas desulphurization pipes and coal slurry conveyor pipelines.

Thickness available: 4mm – 25mm

Shape available: Tubes , Tee pipes, Elbows, Cones, Rings and so on.

The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, coling air pipe,burner nozzles,thermocouple protecting tubes,temperature measuring parts, radiant tubes, desulfurization nozzles, crucible,batts, wear resistant lining materials,plates, seals, rings and special shaped structural parts.

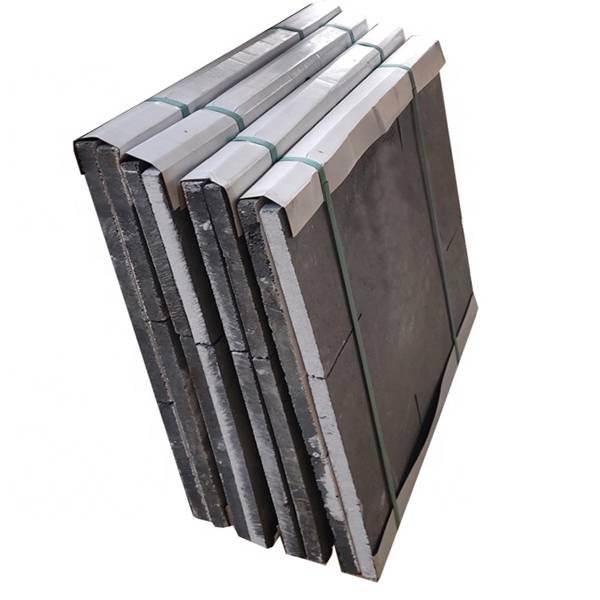

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for High Quality for Nsic - Wear Sleeves Tube – Anteli , The product will supply to all over the world, such as: United Arab Emirates, Netherlands, belarus, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.