Factory selling silicon carbide spray coating - silicon carbide batts – Anteli

Factory selling silicon carbide spray coating - silicon carbide batts – Anteli Detail:

Product detailed

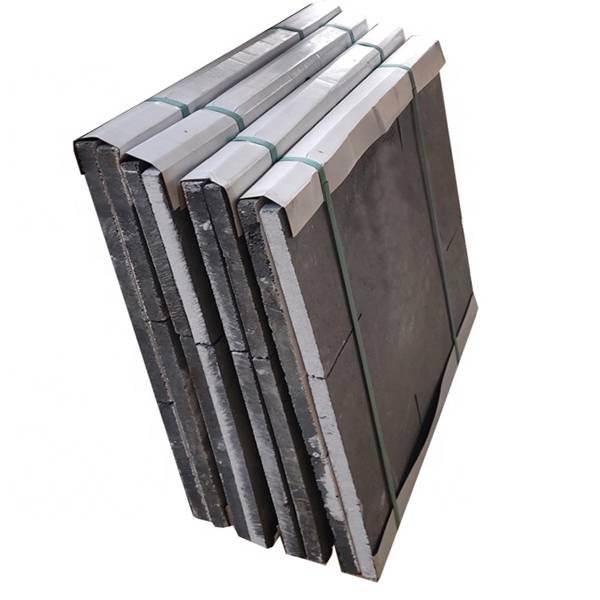

The density is high, the surface is smooth. High temperature and high compressive and flexural strength, no deformation. Quench resistance, good thermal shock resistance, not easy craze. Good oxidation resistance, used to burn into kiln oxidizing atmosphere and reducing atmosphere. Can improve the utilization rate of kiln and the energy saving rate.

Compared with recrystallized and nitride bonded sic, the long-term performance of reaction-sintered sic is better. The flexural strength of reaction-sintered sic is more than twice that of recrystallized sic and about 50% higher than that of nitride bonded sic.

Product specification

According to customer’s size request or drawing

Regular dimension (mm):

600*500 600*470 600*400 500*500 500*370 500*340 500*450 485*460 450*450 450*420 420*380 360*360 340*340 330*330 320*320 310*310mm

Note : Thickness on customer’s requirement

Characteristics

•excellent energy savings.

• Lighter weight and higher load capacity.

• Excellent distortion resistance at high temperature.

• High thermal conductivity

• High Young’s modulus

• Low thermal expansion coefficient

• Extremely high hardness

• High strength

• Wear resistant

• Good oxidation resistance

Technical data

| Technical Parameter | Unit | SiC | SSiC | Sic+C |

| Hardness | HS | 110 | 115 | ≥105 |

| Porosity Rate | % | <0.3 | <0.2 | <0.5 |

| Density | g/cm3 | 3.00~3.05 | >3.10 | 2.69-2.90 |

| Compressive Strength | MPa | >2200 | >2500 | >1400 |

| Fractural Strength | MPa | >350 | >380 | >150 |

| Coefficient of Heat Expansion | 10-6/oC | 4.0 | 4.2 | 3.5 |

| Content of Sic | % | ≥90 | ≥98 | ≥85 |

| Free Si | % | ≤10 | ≤1 | ≤12 |

| Elastic Modulus | GPa | ≥400 | ≥410 | ≥350 |

| Temperature | oC | 1300 | 1400 | 1300 |

Why Choose us?

We have more than 10 years of experience, advanced equipment and professional team in this field. With leading technical strength, excellent operation management and quality service, we are recognized by customers in the chemical industry, petroleum, electric power, metallurgy, building materials, aerospace, machinery and other industries.

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

We strive for excellence, services the customers", hopes to be the top cooperation team and dominator business for personnel, suppliers and prospects, realizes benefit share and continual promotion for Factory selling silicon carbide spray coating - silicon carbide batts – Anteli , The product will supply to all over the world, such as: Thailand, Cambodia, Spain, Furthermore, all of our items are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our goods, please don't hesitate to contact us. We will do our best to meet your needs.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.