Competitive Price for Raw Material For Grinding Wheel - Burner nozzle – Anteli

Competitive Price for Raw Material For Grinding Wheel - Burner nozzle – Anteli Detail:

Description

Reaction bonded silicon carbide sic ceramic burner nozzle has high hardness, high temperature resistance, acid and alkali resistance, oxidation resistance and good thermal shock resistance , which are widely used for heating on direct or indirect furnace systems.

Technical parameters of Reaction bonded silicon carbide sic ceramic burner nozzle:

|

Item |

UNIT |

DATA |

|

Temperature |

℃ |

1380 |

|

Density |

g/cm³ |

≥3.02 |

|

SiC |

% |

≥85 |

|

Open Porosity |

% |

<0.1 |

|

Moh’s Scale of Hardness |

13 |

|

|

Bending Strength |

MPa |

250 (20℃) |

|

MPa |

280 (1200℃) |

|

|

Modulus of Elasticity |

GPa |

330 (20℃) |

|

GPa |

300 (1200℃) |

|

|

Thermal Conductivity |

W/m.k |

45 (1200℃) |

|

Coefficient of thermal expansion |

k-1×10-6 |

4.5 |

|

Acid Alkaline -proof |

Excellent |

Performance

◊ Superior wear resistance, impact resistance and corrosion resistance

◊ Excellent flatness and temperature resistance up to 1380℃

◊ Excellent oxidation resistance

◊ Good dimensional control of complex shapes

◊ Easy installation

◊ Longer service life

◊ No deformaion under for long-term working at high temperature

Aplicacion

Reaction bonded silicon carbide sic ceramic burner nozzle is the key parts of tunnel kiln, shuttle kiln, roller hearth kiln.The silicon carbide burner nozzles can also be used for heating on either direct or indirect furnace systmes.

About Us

Founded in 2011, our company has rich and professional experience in the field of silicon carbide product manufacturing. We have several production lines of silicon carbide with an annual output of 70,000 tons. Our silicon carbide products meet international certification standards and have won unanimous praise in the international market.

The products are exported to dozens of countries around the world.

We have a professional r & D team, a dynamic sales team to meet the needs of customers, looking forward to working with you

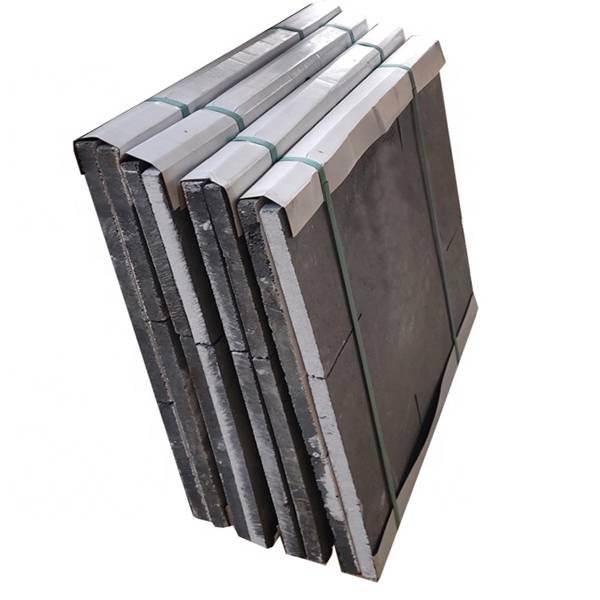

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and advancement, we will build a prosperous future with each other with your esteemed firm for Competitive Price for Raw Material For Grinding Wheel - Burner nozzle – Anteli , The product will supply to all over the world, such as: Norwegian, Lebanon, Macedonia, Many kinds of different solutions are available for you to choose, you can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to deliver more support for customers. Welcome all nice buyers communicate details of solutions with us!!

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!