2020 High quality Vacuum Firing - Silicon Carbide Beam – Anteli

2020 High quality Vacuum Firing - Silicon Carbide Beam – Anteli Detail:

Product detaill:

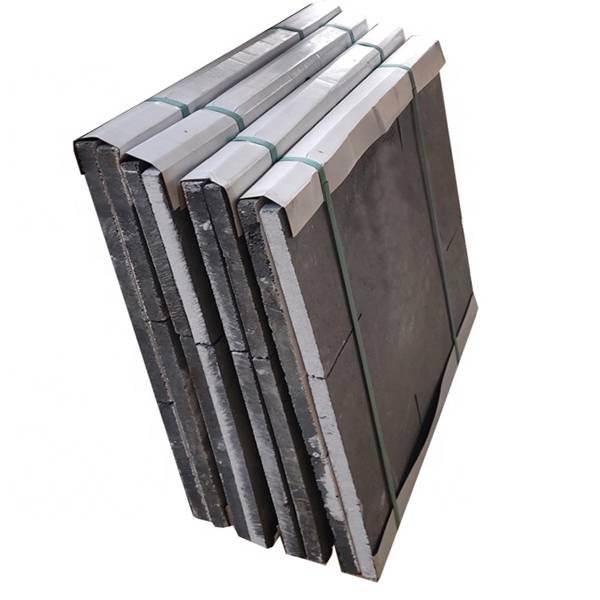

Reaction-sintered silicon carbide square beams are applicable for load-bearing structure frames of tunnel kilns, shuttle kilns, double-layer roller kilns and other industrial kilns. The product features in that the high-temperature bearing capacity is large, there is no bend or deformation in long-term use, and the service life is several times that of other materials, thus it is the ideal kiln furniture for sanitary porcelain and other electrical porcelain industries. The product is characterized with excellent high-temperature flexural strength, thermal shock resistance, oxidation resistance and free deformation in long-term use, thus can significantly reduce energy consumption without increasing the weight of the kiln car.

Major technical indicators of reaction-sintered silicon carbide products

Characteristic:

a.High temperature strength allows heavy loading weight

b.Excellent thermal shock resistance

c.High thermal conductivity

d.Excellent oxidation resistance translates to long life under high working temperature

Application

Silicon nitride and silicon carbide beams have excellent high-temperature flexural strength, creep resistance and oxidation resistance; mainly used in sanitary ceramics, high-voltage electrical porcelain, filters, quartz crucibles; shed plates and fish-shaped plates which are widely used in daily-use ceramic Industry; protection tube is used for temperature measurement in various industries; special-shaped products and burner sleeves are widely used in various kiln and mechanical engineering.

| Item | Data | Data |

| Operating Temperature | ℃ | 1380 |

| Density | g/cm³ | ≥3.02 |

| Porosity | % | < 0.1

|

| Bending Strength | Mpa | 250(20℃) |

| Mpa | 280 (1200℃) | |

| Elastic Modulus | Gpa | 330(20℃) |

| Gpa | 300 (1200℃) | |

| Thermal Conductivity | W/m.k | 45 (1200℃) |

| Thermal Expansion Coefficient | K-1×10-6 | 4.5 |

| Mohs Hardness | 13 | |

| Alkalinity and Acidity | Excellent |

| Length(m) | Sectional Dimensions | Concentrated Bearing Capacity(kg) | Resultant Force of Uniform Distribution Force

(kg)

|

||

| L | B | H | δ | ||

| 1 | 30 | 40 | 6 | 130 | 260 |

| 1 | 40 | 40 | 6 | 165 | 330 |

| 1 | 40 | 50 | 6 | 235 | 470 |

| 1 | 50 | 70 | 7 | 526 | 1052 |

| 1 | 60 | 90 | 9 | 1059 | 2118 |

Product detail pictures:

Related Product Guide:

SiC Conference of Four Provinces and Regions in Western China

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for 2020 High quality Vacuum Firing - Silicon Carbide Beam – Anteli , The product will supply to all over the world, such as: El Salvador, Paraguay, Iceland, Many years of work experience, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!